VAN RACKING SYSTEMS & CONVERSIONS

Modul-System

MODUL-SYSTEM

We can convert your empty van into a fully functioning service vehicle with our modular van racking systems and van shelving. We offer a complete van conversion service in the UK, which in addition to indispensable van racking can include modular floors and van liners, vehicle electrical systems, accessories, vehicle graphics and livery.

We fit racking solutions to a wide range of vans and commercial vehicles including LCVs, MCVs and pick-up trucks through our UK approved installation partners. No matter which business sector you operate within, or what you drive, we have a van racking system to suit your business, whether for a single van or a fleet of vehicles.

BENEFITS

- Modular racking systems with short installation time.

- Lightweight racking allows increased load capacity or lower fuel consumption.

- Good for the environment; lower fuel costs equate to lower CO2 emissions.

- Greater flexibility for your day to day business with customised van storage solutions.

- Extended functionality with accessories to create a more efficient workspace.

- Robust, durable and collision safe vehicle racking conversions.

- Non-intrusive racking installation to protect the vehicle’s residual value.

Customise a kit for your van

We are offering a range of pre-designed kits, tailor-made for each vehicle.

Please select your vehicle below to view the solutions available.

Double floor

For light commercial vehicles in the smaller segment, double floor solutions are becoming increasingly popular. This as they maximise the utilisation of the cargo space.

READ MORE

Extra-long drawers, intended for heavy and bulky cargo, are installed under the double floor. Each drawer has a load capacity of 80 kg, alternatively 100 kg if a rubberized insert is used. The drawers can be extended about 80 per cent and the ball bearing solution makes them both stable and easy to operate. Smart accessories contribute to increased functionality.

The double floor is installed on top of the drawers. For best possible combination of lightweight and robustness, the floors are manufactured from a sandwich material with aluminium on the top and bottom. Edging strips in aluminium are included for a nice finish.

The double floor has integrated cargo rails, which can be used for the fixation of van racking or to secure cargo. Modul-System offer lashing eyelets which are extremely robust and which easily can be moved.

MAXIMISED UTILISATION OF THE CARGO SPACE

A double floor solution maximises the utilisation of the cargo space. Heavy and bulky cargo is placed in the long drawers beneath the double floor and is easily accessible from the outside of the vehicle. The space above the double floor is available for tools and other equipment. It is also possible to install van racking on top of the double floor to maximise the utilisation of the load area.

COLLISION SAFE

For safety reasons, heavy and bulky items are kept in long drawers beneath the double floor. Each drawer is equipped with a CRP (Crash Restraint Panel) which prevents loads from being propelled forward in the event of an accident.

When the double floor solution is installed in the vehicle, it is done with safety in mind. The drawers are fixed with a certain distance in between products to create built-in deformation zones, which prevents them from being pushed into the bulkhead in the event of a rear-end collision.

As an option, we offer an impact safety partition which is mounted close by, and reinforces, the bulkhead. In the event of a rear-end collision, it absorbs the loads from the double floor solution to further protect the driver and passenger.

READ LESS

Accessories

The Modul-System accessories are innovative products that have been specifically developed for use with the Modul-System range. By adding accessories, you can extend the functionality of the racking system and make your workspace even more efficient.

LIGHTWEIGHT AND ROBUST

Modul-System Limited, formerly known as Tevo Limited, is vastly experienced in producing lightweight steel racking systems. We were the first in our industry to introduce high strength steel (HSS) and later ultra-high strength steel (UHSS), into our products. By using this high-tech material, we have been able to reduce the weight of our products even further, while the solutions remain extremely robust and collision-safe.

A lighter weight racking system provides many benefits, including increased load capacity, lower fuel consumption and reduced emissions.

READ MORE

When steel is lighter than aluminium and plastic

Are you struggling with payload? Considering switching to another material to reduce the weight of the racking system? If so, you might want to reconsider.

We have carried out a direct comparison between the current Modul-System Limited, formerly known as Tevo Limited, racking and what the equivalent modules would weigh if produced in another material. Sustained load capacity was a prerequisite for our evaluation.

In conclusion, the system would weigh approximately the same if produced in aluminium, and would be considerably heavier if produced in plastic / composite or mild steel.

| Modul-System | Aluminium | Plastic / composite | High strength steel | Mild steel | |

| Weight | 78 kg | 79 kg | 83 kg | 104 kg | 116 kg |

| Diff. (kg) | +1 kg | +5 kg | +26 kg | +38 kg | |

| Diff. (%) | +1 % | +6 % | +25 % | +33 % |

READ LESS

UHSS - THE ULTIMATE MATERIAL FOR VEHICLE RACKING

On the market today, there are many different steel qualities with different properties. The optimum steel for the job depends on what the product will be used for, and which properties it should have.

Modul-System Limited’s, formerly known as Tevo Limited, ultra-high strength steel (UHSS) is four times stronger than mild steel. Its extreme strength enables constructions in substantially thinner steel plate, which means lighter weight products.

READ MORE

However, designing in ultra-high strength steel is not as easy as it might sound. To get good rigidity with thinner steel, it normally requires modifying the shape.

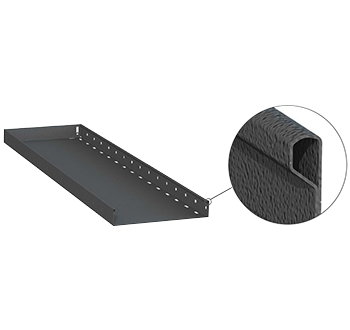

For example, the Modul-System shelves have a rolled edge that counteracts flexure (bending). This patent-pending design allows for a weight reduction of up to 40% compared with the equivalent shelf in mild steel.

MATERIAL COMPARISON

Are you struggling with payload? Considering switching to another material to reduce the weight of the racking system? If so, you might want to reconsider.

We have carried out a direct comparison between the current Modul-System racking and what the equivalent modules would weigh if produced in another material. Sustained load capacity was a prerequisite.

In conclusion, the system would weigh approximately the same if produced in aluminium, and would be considerably heavier if produced in plastic / composite or mild steel.

| Aluminium | Mild steel | HSS | UHSS | |

| Density | 2.7 kg/dm3 | 7.8 kg/dm3 | 7.8 kg/dm3 | 7.8 kg/dm3 |

| Strength | 70-150 MPa | 200 MPa | 350-500 MPa | 700 -1100 MPa |

| E-modulus | 70 GPa | 210 GPa | 210 GPa | 210 GPa |

| Relative density | 1 | 3 | 3 | 3 |

| Relative strength | 1 | 1,5-2 | 3-4 | 4-6 |

| Relative e-modulus | 1 | 3 | 3 | 3 |

| Relative impact resistance | 1 | 2 | 2,5 | 3 |

All steel, regardless of strength, has identical density and e-modulus. This means that products of the same size and shape, whatever the grade of steel, will weigh as much and bend as much when loaded. The difference between them is their strength, where an ultra-high strength steel can bear up to 6 times the load of an equivalent product of aluminium.

READ LESS

LET'S TALK

Do you have any questions or want to schedule an appointment?

Leave your details and we will contact you!

Alternatively, contact our sales team on:

Tel: 01628 528034 or

sales@modul-system.co.uk

Or why not visit our FAQ page and see if your question

has already been answered:

Contact us

HOW TO ORDER

For more information on how to order products through our website, please click here. Alternatively, you can contact our sales team directly using our - contact form, or email: sales@modul-system.co.uk or call us on 01628 528034.

Click to read more about our supply options.

READ MORE

SUPPLY OPTIONS

Our award-winning products are available to order in a range of supply options whether you are a tradesman or the operator of a nationwide fleet. Our fitting options are outlined below and range from a complete fit out and conversion service to flat pack and pre-assembled delivery of our van racking kits.

- Complete fitting service for vans and fleets at our Wooburn Green workshop

- Via our national mobile installation teams

- Flat pack (supply only)

- Pre-assembled

- At one of our nationwide approved service centres

Contact us today to discuss your requirements today.

Email: sales@tevo.eu.com or call us on 01628 528034

READ LESS

Subscribe to our newsletter

Subscribe to our newsletter